Environmental protection equipment

Dissolved air flotation material

Dissolved air flotation (DAF) is a process that creates highly dispersed, tiny air bubbles in water. These bubbles adhere to hydrophobic solid or liquid particles in wastewater, forming a three-phase mixture of water, air, and particles. After the particles attach to the bubbles, they form flocs with an apparent density less than water and float to the surface, forming a scum layer that is removed. This achieves solid-liquid or liquid-liquid separation. Common types include electroflotation, dispersed air flotation, dissolved air flotation, combined flotation, and high-efficiency shallow flotation.

|

|

|

|

Aerator material

Utilizing centrifugal force and the pulverizing action of multi-layer cutters, it creates a gas-water mixture for lifting, stirring, and mixing oxygenation. The mud-water-gas mixture circulates inside and outside the equipment. During the upward movement of gas and liquid inside the equipment, the special internal structure repeatedly cuts the mixture, forming small bubbles. The vigorous stirring of gas and liquid also increases the rapid transfer and dissolution of oxygen.

This equipment is a highly efficient, maintenance-free, and long-life aeration device with advantages such as a large service area, low resistance, stable and reliable operation, and no blockage. It is mainly used in aeration systems for industrial and municipal wastewater treatment, and its advantages are more pronounced in wastewater with high suspended solids, high hardness, and a tendency to scale. It can form aerobic granular sludge, significantly improving the activity of aerobic sludge and the efficiency of aerobic treatment.

|

|

|

|

Micro-power instantaneous separator material

The WSF series micro-power instantaneous separation equipment is a new type of solid-liquid separation equipment. Through the special action of unique additives, it combines solid pollutants in wastewater with the additives. The binding force between the additives and the rotor of the water purifier removes solid pollutants from the wastewater in a very short time. This equipment adopts a unique innovative design and integrates advanced foreign technologies, greatly shortening the solid-liquid separation time while maintaining high removal efficiency and effluent water quality. The entire process consumes only minimal energy, hence it is called a micro-power device.

Unique Advantages:

1. Short hydraulic retention time: The entire solid-liquid separation (mud-water separation) process takes only 3-6 minutes, while traditional processes such as sedimentation require 3 hours or more;

2. Extremely low power consumption: A 300-ton/hour scale device only requires 15 kW, making it a micro-power device;

3. Saves land area: The equipment footprint is one-tenth that of traditional processes.

4. Simple and convenient operation, high degree of automation, saving labor costs.

5. Low sludge moisture content, reaching below 95%;

6. Saves sludge storage space, eliminates the need for sludge thickening, saves sludge filter press equipment, and reduces the requirements for sludge filter press facilities compared to traditional processes;

7. Very suitable for expansion projects and technical transformation projects.

|

|

|

|

Integrated equipment material

Integrated wastewater treatment equipment integrates primary sedimentation tanks, I and II level contact oxidation tanks, secondary sedimentation tanks, and sludge tanks. It uses air blowing in the I and II level contact oxidation tanks, effectively combining contact oxidation and activated sludge methods. It combines the advantages of both while overcoming their disadvantages, further improving wastewater treatment levels. Integrated wastewater treatment equipment is suitable for residential areas, villages, towns, office buildings, shopping malls, hotels, restaurants, sanatoriums, government offices, schools, military units, hospitals, highways, railways, factories, mines, tourist attractions, and other domestic wastewater and similar small-scale industrial organic wastewater treatment and reuse, such as slaughterhouses, aquatic product processing, and food processing.

|

|

|

|

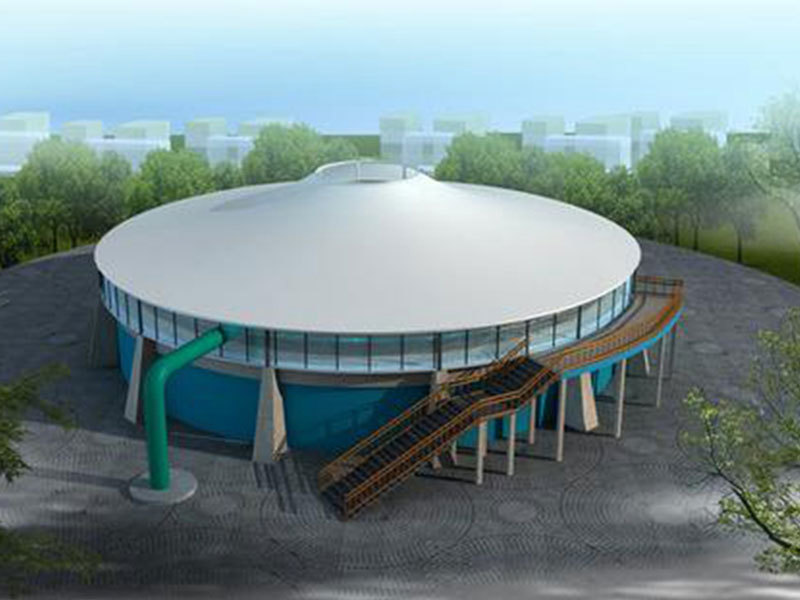

Corrosion-resistant exhaust gas collection system

Fluorocarbon fiber membranes are mainly used in environmental engineering such as biogas and wastewater treatment pools. Fluorocarbon fiber membrane materials use special coating materials to ensure that methane is not easily permeable. The membrane material has high strength, ensuring that the biogas tank can withstand damage from typhoons and heavy snow in outdoor environments. The corresponding materials for fluorocarbon fiber membranes have UV resistance, cold resistance, heat resistance, and mildew prevention functions to prevent corrosion and ensure durability.

Active rotary steel frame support inverted fluorocarbon fiber membrane wastewater pool sealing cover, including the first support ring, exhaust main pipe, exhaust gas collection and conversion device, fluorocarbon fiber membrane, drive device, supporting wheel, first support frame, and multiple second support frames. The exhaust gas collection and conversion device is connected to the first support frame and located above the fluorocarbon fiber membrane, and the exhaust main pipe penetrates the center of the fluorocarbon fiber membrane and is connected to the exhaust gas collection and conversion device. Meiquan Environmental Protection's sealing cover has low construction cost, light weight, and protects the scraper bridge from corrosive gases.

|

|

|

|

Address: 16th Floor, East District, Building 1, Shun Tai Plaza, Gaoxin District, Jinan City, Shandong Province

Tel: +86-5318756 5188 +86-4006788635

Fax: +86-53187568555

Email: mqhb@china-meiquan.com

© 2022 Shandong Meiquan Environmental Protection Technology Co.,Ltd.