Corrosion-resistant exhaust gas collection system

Category: Engineering Cases

Keywords: Product development, technological research, project survey and design, engineering installation

Hotline:

Corrosion-resistant exhaust gas collection system

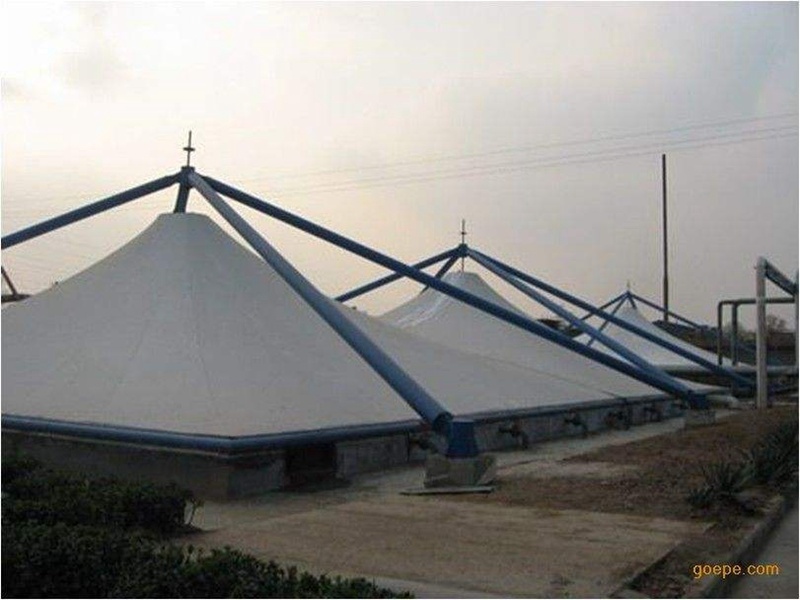

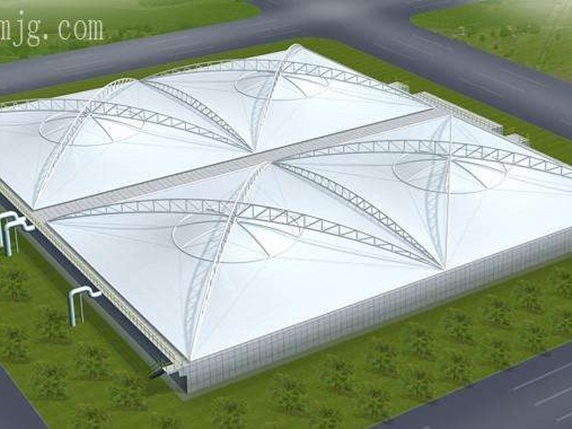

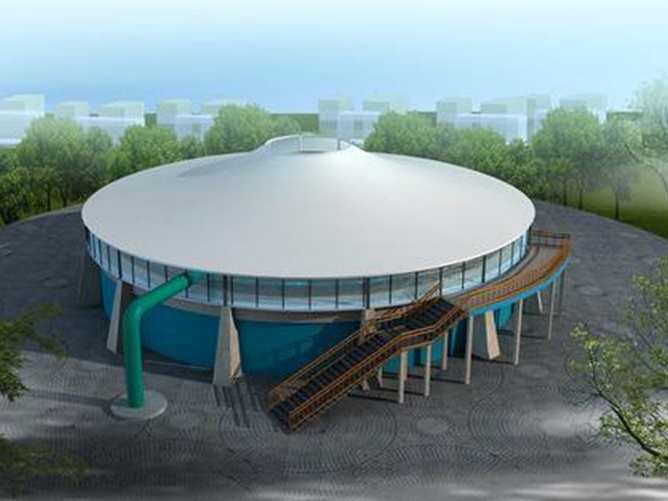

Fluorocarbon fiber membranes are mainly used in environmental engineering projects such as biogas and wastewater treatment ponds. The fluorocarbon fiber membrane material uses a special coating to prevent methane permeation. The membrane material is highly strong, ensuring that the biogas tank can withstand damage from severe weather such as typhoons and heavy snow outdoors. Fluorocarbon fiber membranes are treated to be UV resistant, cold resistant, heat resistant, and mildew proof, preventing corrosion and ensuring durability.

An actively rotating steel frame support inverted fluorocarbon fiber membrane wastewater pool sealing cover includes a first support ring, an exhaust main pipe, an exhaust gas collection and conversion device, a fluorocarbon fiber membrane, a drive device, a supporting wheel, a first support frame, and multiple second support frames. The exhaust gas collection and conversion device is connected to the first support frame and located above the fluorocarbon fiber membrane, and the exhaust main pipe penetrates the center of the fluorocarbon fiber membrane and communicates with the exhaust gas collection and conversion device. Meiquan Environmental's sealing cover has low construction costs, a lightweight structure, and protects the scraper bridge from corrosive gases.

Meiquan's progress and development are based on a deep understanding and maximum satisfaction of customer needs. Meiquan closely follows the pace of advanced technology, constantly improving after-sales service and providing timely and diversified training for employees, using its own expertise to help customers meet environmental challenges. The company's core technologies, such as the circulating granular sludge reactor (MQIC), upflow anaerobic sludge bed reactor (H-UASB), segmented inflow biological denitrification process (BRN), and ammonia oxidation biological denitrification process (AMOXP), have all been fully verified in engineering practice and have high efficiency, low carbon, innovation, and leading advantages in the environmental protection field.

The company takes "the harmonious unity of advanced technology and high-quality service, and the perfect combination of environmental protection and resource utilization" as its tenet. Relying on technological innovation and scientific management, carrying forward the enterprise spirit of "integrity, innovation, efficiency, and pragmatism," achieving the company's self-improvement and development, providing high-quality services to society with characteristics and brands, and with diligent spirit and work attitude, providing you with the most advanced technology, the best quality service, and the most perfect solutions in the field of wastewater treatment.

Customer Message

If you are interested in our products and services, please contact us immediately.

Product Recommendation

Address: 16th Floor, East District, Building 1, Shun Tai Plaza, Gaoxin District, Jinan City, Shandong Province

Tel: +86-5318756 5188 +86-4006788635

Fax: +86-53187568555

Email: mqhb@china-meiquan.com

© 2022 Shandong Meiquan Environmental Protection Technology Co.,Ltd.